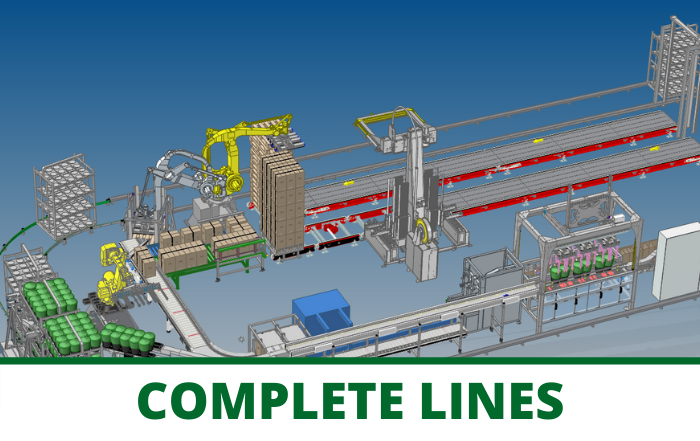

Our services

WE DESIGN AND DEVELOP INNOVATIONS THAT LEAD TO GROWTH.

recent projects

WE PROUDLY PRESENT OUR SOLUTIONS FOR PLANT AND FOOD PROCESSING.

We realize high-tech automatization concepts for Enterprises aimed to grow.

CRATE (DE)STACKER

Stacking and destacking crates can be labor intensive and monotonous work. Crea-Tech created a solution to improve this process; the crate (de)stacker. This automatically stacks the crates, but also destacks them. [...]

TRAY SPACING

When the plants have grown enough they will need more space to grow. The cart can be manually placed into a Crea-Tech cart unloader, the cart will move to the robot position where a [...]

POTTED ROSES AUTOMATION

Another great Crea-Tech project, if we do say so ourselves. It concerns an automated solution for the internal transport of pot roses between the two greenhouses; consisting of, among other things, a Trolley unloader, [...]

Our machines

Forward Thinking In Robotics, Engineering and Design.

latest news

ALWAYS IN MOTION.

Ronald Moerings Foundation

Members of the Ronald Moerings Foundation gathered last Friday to listen to physician-researcher Jessica Borgers from the Antoni van Leeuwenhoek. She shared one of the latest studies on immunotherapy [...]

Official Organisation Covid-19 Statement

Crea-Tech operates internationally and obviously our customers are interested in which measures we have taken to avoid the infection and spread of the coronavirus (Covid-19). The National Institute for [...]

Open day Ronald Moerings Foundation

Our annual visit to the Antoni van Leeuwenhoek (AVL) Cancer hospital this year was Friday, 15 November. We (Henk and Paul) arrived at 3:30 pm at the AVL hospital, [...]

about us

WHERE WE CAME FROM.

We believe that automation leads to more labor, contributing to a better nature by producing more efficient and growing faster. The total productivity gains will come about only if people work alongside machines. That, in turn, will fundamentally alter the workplace, requiring a new degree of cooperation between workers and technology. Growth is the result of working together.

some testimonials

What clients say about us.

Feedback is a critical component of successful collaboration.

ULF JÖNNSON

Head of Development

Spisa Group

BJÖRN BUNNIK

Owner

Bunnik Vriesia’s

PAUL VAN DER SALM

Owner

Kwekerij Salm Boskoop